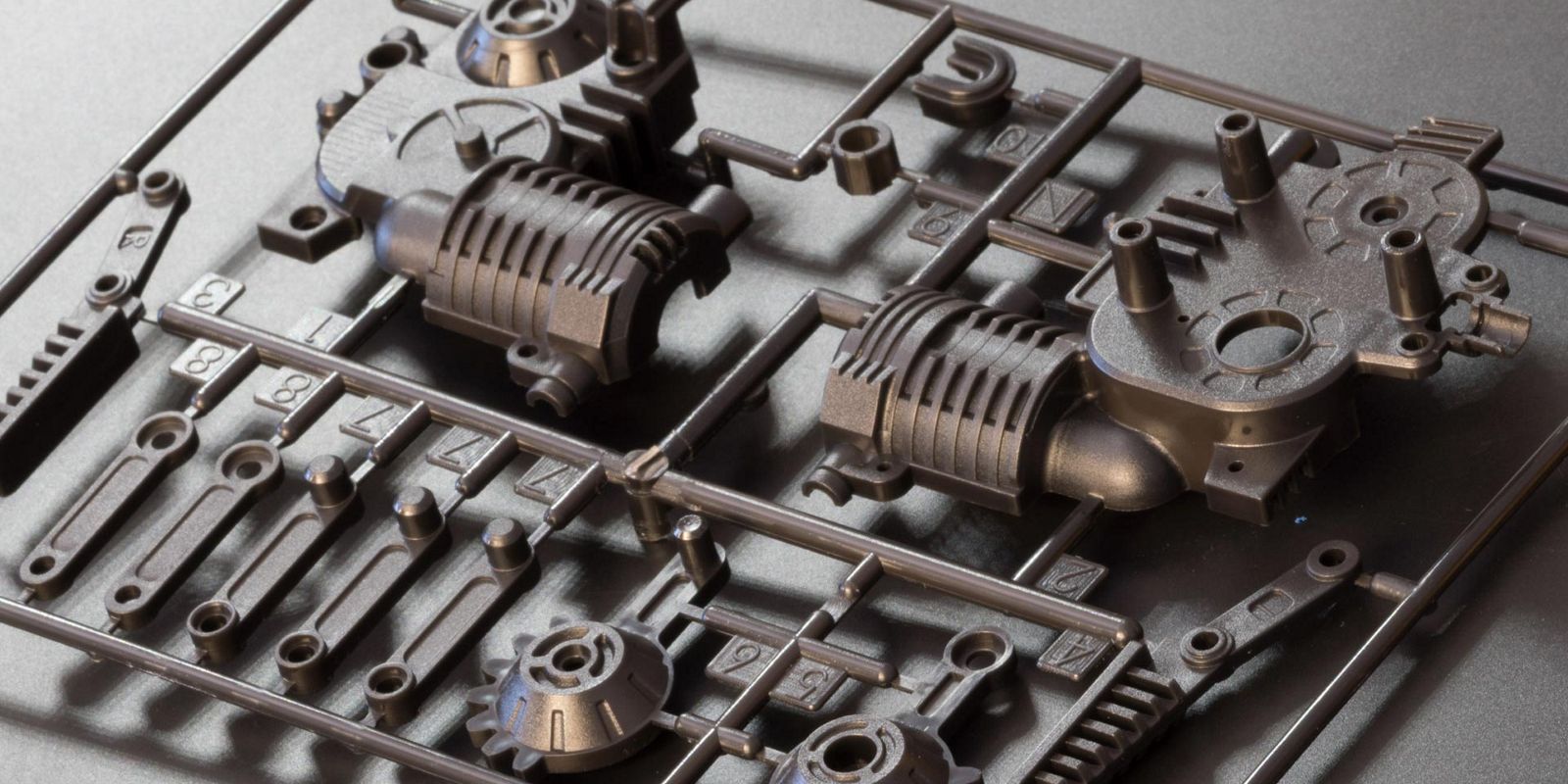

From powder to the final product

How do we guarantee our high product standards? By ensuring that we do it all ourselves. Our process chain starts with the reduction of the powder. This enables us to take targeted control regarding material properties every step along the way. Reliability and consistency have been of great concern to us for one hundred years. Especially when it comes to our raw material supply. To keep this secure, we only deal with Western mines. Our in-house production and our international manufacturing network also help to ensure guaranteed delivery capability.

Our employees really know their way around metals due to their decades of experience. Your advantage: the highest product quality and absolute precision.